PD Dr. Andreas Vorholt - Multiphase Catalysis

- PD Dr. Andreas Vorholt

- Group leader

- Multiphase Catalysis

- Molecular Catalysis

- +49 (0)208 306 - 3157

- andreas-j.vorholt(at)cec.mpg.de

- Room: 671

Vita

| Diploma (Chemistry) | TU Dortmund (2003-2008) |

| Semester abroad | University of Queensland, Brisbane, Australia (2007) |

| Master of Science | Economic Sciences, TU Dortmund (2009-2011) |

| Doctorate (Dr. rer. nat.) | Industrial Chemistry (summa cum laude), TU Dortmund (2008-2011) |

| Consultant | Implementation of LEAN Management in middle size production enterprises (since 2012) |

| Assistant professor (Habilitation) | Institute for Technische Chemie, TU Dortmund; Manager of a new independent research group for Resource Efficient Chemistry (2012-2017) |

| Visiting scientist | With Dr. M. V. Garland at A*Star Institute for Chemical and engineering sciences, Singapore (01/2015-04/2015) |

| Lectureship | Institute for Industrial Chemistry & Petrochemistry, RWTH Aachen: multiphasic catalysis and immobilisation (since 2016) |

| Lectureship | Institute for Technische Chemie, TU Dortmund: value added in chemical industry & chemical processes in case studies (since 2018) |

| Group leader | 'Multiphase Catalysis', MPI CEC (since 2018) |

| Habilitation Venia Legendi Technical Chemistry | TU Dortmund (2018) |

| Deputy professor | Technical Chemistry and Petrol Chemistry, RWTH Aachen (since 10/2018) |

Publications

Full publications list | ORCID | list of patents

Selected MPI CEC publications

- Vossen, J. T., Leitner, W., Vorholt, A. J. (2023). Exploring the Hurdles in Thermomorphic Multicomponent Systems in the Rhodium-Catalyzed Multiphase Hydroformylation. ACS Sustainable Chemistry & Engineering, (11), 10462-10470. doi:10.1021/acssuschemeng.3c01885.

- Vossen, J. T., Hülsken, N., Vorholt, A. J., Leitner, W. (2023). Recycling of a thermoresponsive "catalyst pill": separation of a molecular catalyst in solid ethylene carbonate in various reactions. Green Chemistry, (25), 2872-2880. doi:10.1039/d2gc04822a.

- October, J., Köhnke, K., Thanheuser, N., Vorholt, A. J., Leitner, W. (2022). Reppe-Carbonylation of Alkenes with Carboxylic Acids: A Catalytic and Mechanistic Study. European Journal of Organic Chemistry, 2022(43): e202201018, pp. 1-7. doi:10.1002/ejoc.202201018.

- Ehmann, K. R., Nisters, A., Vorholt, A. J., Leitner, W. (2022). Carbon Dioxide Hydrogenation to Formic Acid with Self-Separating Product and Recyclable Catalyst Phase. ChemCatChem, 14(19): e2022008, pp. 1-7. doi:10.1002/cctc.202200892.

- Rösler, T., Betting, J., Püschel, S., Vorholt, A. J., Leitner, W. (2022). Solvent design for catalyst recycling of rhodium/amine catalysts via scCO(2) extraction in the reductive hydroformylation of alpha olefins. Green Chemistry, 24(17), 6578-6588. doi:10.1039/d2gc01252a.

- Strohmann, M. P., Vorholt, A. J., Leitner, W. (2022). Branched Tertiary Amines from Aldehydes and alpha-Olefins by Combined Multiphase Tandem Reactions. CHEMISTRY A EUROPEAN JOURNAL, (xx): e202202081, pp. 1-8. doi:10.1002/chem.202202081.

- Rösler, T., Betting, J., Püschel, S., Vorholt, A. J., Leitner, W. (2022). Solvent Design for the Catalyst Recycling of Rhodium/Amine Catalysts via scCO2 Extraction in the Reductive Hydroformylation of Alpha Olefins. Green Chem., accepted, DOI: 10.1039/D2GC01252A

- Strohmann, M., Vorholt, A. J., Leitner, W. (2022) Branched Tertiary Amines from α-Olefins by Combined Multiphase Tandem Reactions. Chem. Eur. J., accepted

- Püschel, S., Sadowski J., Rösler, T., Ehmann, K. R., Vorholt, A. J., Leitner, W. (2022). Auto-tandem catalytic reductive hydroformylation in a CO2-switchable solvent system. ACS Sus. Chem.& Eng. 10, (11), 3749–3756, DOI: 10.1021/acssuschemeng.2c00419

- Schrimpf, M., Graefe, P. A., Holl, A., Vorholt, A. J., Leitner, W. (2022). Effect of Liquid-Liquid Interfacial Area on Biphasic Catalysis Exemplified by Hydroformylation. ACS Catalysis, (12), 7850-7861. doi:10.1021/acscatal.2c01972. Highlighted as cover picture DOI: link

- Jeske, K., Rösler, T., Belleflamme, M., Rodenas, T., Fischer, N., Claeys, M., Leitner, W., Vorholt, A. J., Prieto, G. (2022). Direct Conversion of Syngas to Higher Alcohols via Tandem Integration of Fischer-Tropsch Synthesis and Reductive Hydroformylation. Angewandte Chemie, International Edition in English, e202201004, pp. 1-9. doi:10.1002/anie.202201004. Highlighted as cover picture DOI: 10.1002/anie.202201004

- Vossen, J. T., Vorholt, A. J., Leitner, W. (2022). Catalyst Recycling in the Reactive Distillation of Primary Alcohols to Olefins Using a Phosphoric Acid Catalyst. ACS SUSTAINABLE CHEMISTRY & ENGINEERING, 10(18), 5922-5931. doi:10.1021/acssuschemeng.2c00237.

- Hombach, L., Simitsis, N., Vossen, J. T., Vorholt, A. J., Beine, K. (2022). Solidified and Immobilized Heteropolyacids for the Valorization of Lignocellulose. ChemCatChem, e202101838, pp. 1-19. doi:10.1002/cctc.202101838.

- Köhnke, K., Wessel, N., Esteban, J., Jing, J., Vorholt, A. J., Leitner, W. (2022). Operando monitoring of mechanisms and deactivation of molecular catalysts. Green Chemistry, 24(5), 1951-1972. doi:10.1039/d1gc04383h.

- Püschel, S., Hammami, E., Rösler, T., Ehmann, K. R., Vorholt, A. J., Leitner, W. (2022). Auto-tandem catalytic reductive hydroformylation with continuous multiphase catalyst recycling. Catalysis Science & Technology (7) 728-736. doi:10.1039/d1cy02000e.

- Kreissl, H., Jin, J., Lin, S.-H., Schütte, D., Störtte, S., Levin, N., Chaudret, B., Vorholt, A., Bordet, A. Leitner, W. (2021). Commercial Cu2Cr2O5 Decorated with Iron Carbide Nanoparticles as Multifunctional Catalyst for Magnetically Induced Continuous Flow Hydrogenation of Aromatic Ketones. Angewandte Chemie, International Edition in English, (xx), xx-xx. doi:10.1002/anie.202107916.

- Rösler, T., Ehmann, K. R., Köhnke, K., Leutzsch, M., Wessel, N., Vorholt, A. J., Leitner, W. (2021). Reductive hydroformylation with a selective and highly active rhodium amine system. Journal of Catalysis, 400, 234-243. doi:10.1016/j.jcat.2021.06.001.

- Püschel, S., Störtte, S., Topphoff, J., Vorholt, A. J., Leitner, W. (2021). Green process design for reductive hydroformylation of renewable olefin cuts for drop-in diesel fuels. ChemSusChem, (14), 5226-5234 . doi:10.1002/cssc.202100929.

- Schrimpf, M., Esteban, J., Warmeling, H., Färber, T.,Behr, A., Vorholt, A. J. (2021) Taylor-Couette reactor: Principles, design, and applications. Aiche Journal, Early Access, e17228 (24pp) https://doi 10.1002/aic.17228

- Strohmann, M., Vossen, J.T., Vorholt, A.J., Leitner, W. (2020). Recycling of two molecular catalysts in the hydroformylation/aldol condensation tandem reaction using one multiphase system Green Chemistry 22(23), 8444-8451. https://doi.org/10.1039/D0GC03392H

- Terhorst, M., Plass, C., Hinzmann, A., Guntermann, A., Jolmes, T., Rösler, J., Panke, D., Gröger, H., Vogt, D., Vorholt, A.J., Seidensticker, T. (2020). One-pot synthesis of aldoximes from alkenes via Rh-catalysed hydroformylation in an aqueous solvent system Green Chemistry 22(22), 7975-7982. https://doi.org/10.1039/D0GC03141K

- Terhorst, M., Heider, C., Vorholt, A.J., Vogt, D., Seidensticker, T. (2020). Productivity leap in the homogeneous ruthenium-catalyzed alcohol amination through catalyst recycling avoiding volatile organic solvents ACS Sustainable Chemistry & Engineering 8(27), 9962-9967. https://doi.org/10.1021/acssuschemeng.0c03413

- Esteban, J., Vorholt, A.J., Leitner, W. (2020). An overview of the biphasic dehydration of sugars to 5-hydroxymethylfurfural and furfural: a rational selection of solvents using COSMO-RS and selection guides Green Chemistry 22(7), 2097-2128. https://doi.org/10.1039/C9GC04208C

- Terhorst, M., Kampwerth, A., Marschand, A., Vogt, D., Vorholt, A.J., Seidensticker, T. (2020). Facile catalyst recycling by thermomorphic behaviour avoiding organic solvents: a reactive ionic liquid in the homogeneous Pd-catalysed telomerisation of the renewable β-myrcene Catalysis Science & Technology 10(6), 1827-1834. https://doi.org/10.1039/C9CY02569C

- Vogelsang, D., Vondran J., Hares, K., Schäfer, K., Seidensticker, T., Vorholt, A.J. (2020). Palladium catalysed acid‐free Carboxytelomerisation of 1,3‐Butadiene with Alcohols accessing Pelargonic Acid Derivatives including Triglycerides under selectivity control Advanced Synthesis & Catalysis 362(3), 679-687. https://doi.org/10.1002/adsc.201901383

- Strohmann, M., Bordet, A., Vorholt, A.J., Leitner, W. (2019). Tailor-Made Biofuel 2 Butyltetrahydrofuran from the Continuous Flow Hydrogenation and Deoxygenation of Furfuralacetone Green Chemistry 21(23), 6299-6306. https://doi.org/10.1039/c9gc02555c

- Bianga, J., Künnemann, K.U. Gaide, T., Vorholt, A.J., Seidensticker, T., Dreimann, M., Vogt, D. (2019). Thermomorphic Multiphase Systems ‐ Switchable Solvent Mixtures for the Recovery of Homogeneous Catalysts in Batch and Flow Processes Chemistry - A European Journal 25(50), 11586-11608. https://doi.org/10.1002/chem.201902154

- Esteban, J., Warmeling, H., Vorholt, A.J. (2019). Utilization of deep eutectic solvents based on choline chloride in the biphasic hydroformylation of 1-decene with rhodium complexes Catalysis Communications 129, 105721. https://doi.org/10.1016/j.catcom.2019.105721

- Plass, C., Hinzmann, A., Terhorst, M., Brauer, W., Oike, K., Yavuzer, H., Asano, Y., Vorholt, A.J., Betke, T., Gröger, H. (2019). Approaching Bulk Chemical Nitriles from Alkenes: A Hydrogen Cyanide-Free Approach through Combination of Hydroformylation and Biocatalysis ACS Catalysis 9, 5198-5203. https://doi.org/10.1021/acscatal.8b05062

- Dreimann, J.M., Kohls, E., Warmeling, H.F.W., Stein, M., Guo, L.F., Garland, M., Dinh, T.N., Vorholt, A.J. (2019). In-situ infrared spectroscopy as a tool for monitoring molecular catalyst for hydroformylation in continuous processes ACS Catalysis 9, 4308–4319. https://doi.org/10.1021/acscatal.8b05066

- Schrimpf, M., Esteban, J., Rösler, T., Vorholt, A.J., Leitner, W. (2019). Intensified Reactors for Gas Liquid-Liquid Multiphase Catalysis: from Chemistry to Engineering Chemical Engineering Journal 372, 917-939. https://doi.org/10.1016/j.cej.2019.03.133

- Esteban, J., Warmeling, H., Vorholt, A.J. (2019). An Approach to Chemical Reaction Engineering and Process Intensification for the Lean Aqueous Hydroformylation Using a Jet Loop Reactor Chemie Ingenieur Technik 91(5), 560-566. https://doi.org/10.1002/cite.201800137

- Kuhlmann, R., Künnemann, K.U., Hinderink, L., Behr, A., Vorholt, A.J. (2019) CO2 based synthesis of various formamides in miniplant scale: a two-step process design ACS Sustainable Chemistry & Engineering 7(5), 4924-4931. https://doi.org/10.1021/acssuschemeng.8b05477

- Faßbach, T.A., Vorholt, A.J., Leitner, W. (2019). The Telomerization of 1,3 Dienes – A Reaction Grows Up ChemCatChem 11(4), 1153-1166. https://doi.org/10.1002/cctc.201801821

- Rösler, T., Faβbach, T.A., Schrimpf, M., Vorholt, A.J., Leitner, W. (2019). Towards water-based recycling techniques: Methodologies for homogeneous catalyst recycling in liquid/liquid multiphase media and their implementation in continuous processes Industrial & Engineering Chemistry Research 58(7), 2421-2436. https://doi.org/10.1021/acs.iecr.8b04295

- Fuchs, S., Lichtem D., Jolmes, T., Rösler, T., Meier, G., Strutz, H., Behr, A., Vorholt, A.J. (2018). Synthesis of industrial primary diamines via intermediate diols - combining hydroformylation, hydrogenation and amination ChemCatChem 10(18), 4126-4133. https://doi.org/10.1002/cctc.201800950

- Vogelsang, D., Vondran, J., Vorholt, A.J. (2018). One-step palladium catalysed synthetic route to unsaturated pelargonic C9-amides directly from 1,3-butadiene Journal of Catalysis 365,24-28. https://doi.org/10.1016/j.jcat.2018.06.004

- Vogelsang, D., Dittmar, M., Seidensticker, T., Vorholt, A.J. (2018). Palladium-catalysed carboxytelomerisation of β-myrcene to highly branched C21-esters Catalysis Science & Technology 8, 4332-4337. https://doi.org/10.1039/C8CY00769A

- Hernandez, R., Dreimann, J.M., Vorholt, A.J., Behr, A., Engell, S. (2018). An Iterative Real-time Optimization Scheme for the Optimal Operation of Chemical Processes under Uncertainty. Proof of Concept in a Miniplant Industrial & Engineering Chemistry Research 57(26), 8750-8770. https://doi.org/10.1021/acs.iecr.8b00615

- Faßbach, T.A., Püschel, S., Behr A., Romanski, S., Leinweber, D., Vorholt, A.J. (2018). Towards a process for the telomerization of butadiene with N-methylglucamine Chemical Engineering Science 181, 122-131. https://doi.org/10.1016/j.ces.2018.02.012

- Vogelsang, D., Faβbach, T.A., Kossmann, P.P., Vorholt, A.J. (2018). Terpene-Derive Highly Branched C30-Amines via Palladium-Catalysed Telomerisation of β-Farnesene Advanced Synthesis & Catalysis 360(10), 1987-1991. https://doi.org/10.1002/adsc.201800089

- Faβbach, T.A., Sommer, F.O., Vorholt, A.J. (2018). Hydroaminomethylation in Aqueous Solvent Systems - An Efficient Pathway To Highly Functionalized Amines Advanced Synthesis & Catalysis 360 (7), 1473-1482. https://doi.org/10.1002/adsc.201701463

- Dreimann, J., Behr, A., Vorholt, A.J. (2018). Reaktoren für Fluid-Fluid-Reaktionen: Strahldüsenreaktoren Handbuch Chemische Reaktoren 1-28. https://doi.org/10.1007/978-3-662-56444-8_29-1

Scholarships and Awards

| 2023 | DECHEMA Award | |

| 2018 | Jochen Block Prize of the Gecats, German society for catalysis | |

| 2017 | Professor Young talent award, DECHEMA | |

| 2017 | Carl-Zerbe-Award of German Society for Petroleum, Coal Science & Technology (DGMK) | |

| 2016 | H.P. Kaufmann-Award of German Society for Fat and Oil Science (DGF) | |

| 2015-2017 | Member of the Global Young Faculty, Mercatorstiftung | |

| 2007 | Study Abroad Scholarship of the Konrad Adenauer Stiftung | |

| 2004-2008 | Scholarship of the Konrad Adenauer Stiftung (KAS) |

Group members

Open positions

The group of Multiphase Catalysis is always seeking new talented students. Exceptionally qualified applicants are welcome to get in touch with Dr. Vorholt at any time. Such enquiries should include a curriculum vitae and a cover letter mentioning eligible fellowship funding agencies to whom you might apply to support your stay in the group. We are more than willing to assist you in the preparation of these applications. In addition, please have two letters of recommendation sent to PD Dr. Vorholt by academic mentors who have previously supervised your work. Job openings of the MPI CEC.

Vacant Bachelor and Master Positions

-

Research Internship | Master Thesis

Research Internship | Master Thesis

Miniplants | Homogeneous Catalysis | Tandem Catalysis

New tandem reaction concepts in miniplants

220 KB -

Bachelor or Master Thesis

Bachelor or Master Thesis

Miniplants | Heterogeneous Catalysis | Modeling | Chemical Reaction Engineering | Process Engineering

425 KB -

Research Internship | Bachelor Thesis | Master Thesis

Research Internship | Bachelor Thesis | Master Thesis

Mini-plants | Multiphase catalysis | Reaction engineering

Investigation of Liquid-Liquid Interfaces

247 KB -

Master Thesis | Research Internship

Master Thesis | Research Internship

Homogeneous catalysis | Catalyst recycling

New concepts for catalyst recycling in Batch system

148 KB -

Master Thesis

Master Thesis

homogeneous catalysis | operando spectroscopy | catalyst deactivation

198 KB -

Master Thesis

Master Thesis

Miniplants | Homogeneous catalysis | Catalyst recycling

New concepts for catalyst recycling in miniplants

183 KB -

Master Thesis / Research Internship

Master Thesis / Research Internship

homogeneous catalysis | tandem catalysis | methanol economy

190 KB -

Master Thesis

Master Thesis

Miniplants | Multiphase catalysis | Reaction engineering

213 KB

Research in Multiphase Catalysis

The transition from a fossil resource-based economy to one relying on renewable energy and feedstocks does not come without multiple challenges, among which is the chemical transformation of resources for energy storage and materials.

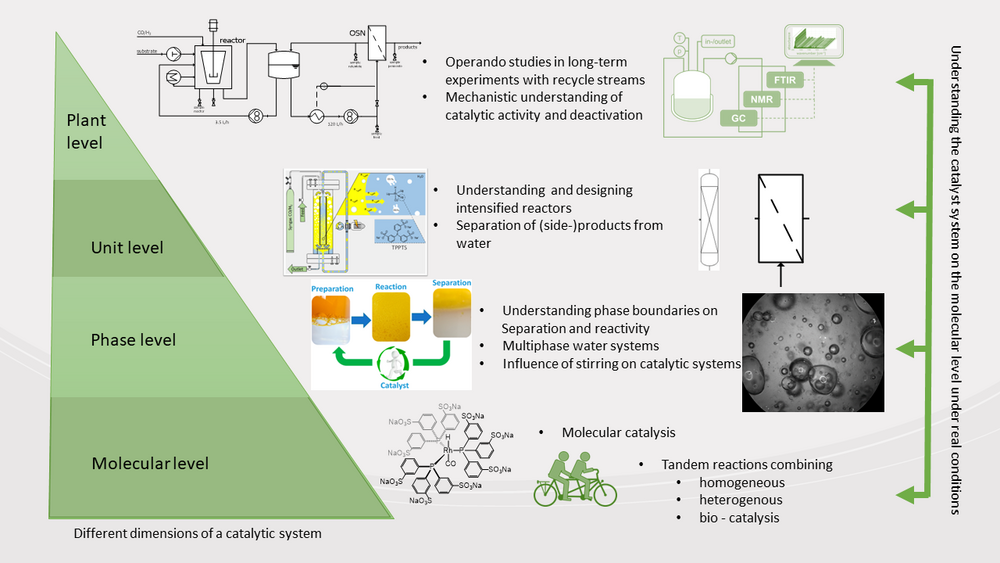

We at the multiphase catalysis group, within the department of molecular catalysis, want to tackle the research in chemical reaction following a multiscale approach to gain a deeper understanding of the underlying phenomenology, starting from the molecular and phase behaviors up to the process level to make them more sustainable and efficient.

The development of this knowledge falls at the interface between Catalysis, Chemical Reaction Engineering and Process Intensification, to which the Green Chemistry principles must be added. For this reason, the work of this group joins the forces of Chemistry and Chemical Engineering to undertake a series of lines of work, including:

- Proposal of new reaction schemes to obtain substitute products to existing goods (e.g., fuels) from alternative starting resources.

- Study of different recycling strategies for homogeneous catalysts in multiphase systems combining computational predictions with experimental efforts.

- Development of novel reactor concepts for intensified catalysis to enhance mass transfer and catalyst recyclability.

The overall goal is to use the knowledge acquired in these aspects to conduct the implementation of process concepts at the miniplant scale with a focus on flow chemistry and on-line analytics to monitor the long-term stability of catalysts.